Why Contractors Prefer Aluminum Honeycomb Panels for Large-Scale Projects

Introduction

Builders base their building material selection on how well materials deliver results including efficiency while lasting long and saving money. Contractors work on larger and complex builds to find new solutions that combine strong support with easy design changes. Construction projects rely heavily on aluminum honeycomb panels because of their recent breakthrough in popularity.

These hollow-core panels provide optimal strength-to-weight performance which explains their widespread use across many industrial fields including design and transport platforms. But why contractors select aluminum honeycomb panels instead of traditional materials? This report explains how aluminum honeycomb panels offer advantages for major construction work.

What You Need to Know About Aluminum Honeycomb Panels

How Do Aluminum Honeycomb Panels Function?

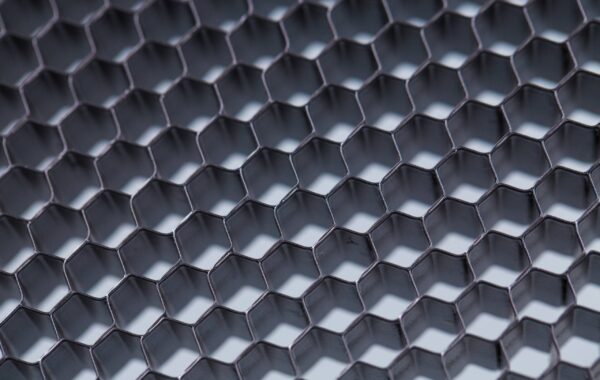

Honeycomb aluminum panels join two slim aluminum sheets to a special honeycomb core produced from aluminum. The two aluminum sheets bond to create a honeycomb design that needs hexagons to deliver high strength and stability while staying light-weight.

How Do They Work?

The honeycomb design structure in the panel smoothly shifts weight throughout the material so it won’t break under pressure. Their quality works best when buildings need frame support and stay lightweight.

Common Uses of Aluminum Honeycomb Panels

These panels are used in a variety of large-scale projects and industries, including:

- High-rise building designers use architectural facades to cover and enclose their exterior walls.

- Manufacturers adopt these panels for their lighter structures that work equally strong within transportation means including planes, trains, buses, and ships.

- Interior design and furniture industries utilize aluminum honeycomb panels to create stylish, modern partitions, ceilings, doors, and countertops.

- Sterile environments benefit from the seamless no-porous surfaces of our panels which ensure easy sanitation.

Key Benefits of Aluminum Honeycomb Panels

1. Lightweight Building Components Have Superior Strength Levels

Aluminum honeycomb panels deliver outstanding strength with minimal density as their main benefit. Structures using traditional materials like steel or concrete need extra weight which drives up the construction cost and creates installation problems.

Builders achieve maximum strength while using less weight with aluminum honeycomb panels, as these panels can be transported and installed with significantly less stress and expense.

Example:

A solid aluminum component of matching thickness would require much more weight to build than an aluminum honeycomb panel which reduces both building content weight and construction speed at project locations.

2. Honeycomb Aluminum Works Well In Different Environments And Stays Strong.

Panel made from aluminum honeycomb material stand up well against rough weather making them first choice for outside and water settings.

- Unlike steel, aluminum does not experience corrosion, so it works well in humid coastal environments.

- Fire-resistant coatings are available on selected variants making structures safer for commercial properties.

- This material stays unaffected by temperature changes between very cold and very hot.

Example:

Contractors working on airport terminal projects should consider aluminum honeycomb panels because they resist damage and fire threats effectively through minimal maintenance.

3. These Materials Lower The Cost Of Large Development Projects.

In all major building projects managing costs remains a top concern. Aluminum honeycomb panels provide long-term savings in several ways:

- The panels save on fuel because they remain very light throughout transportation.

- Installation processes take less time which reduces labor expenses and gets projects finished sooner.

- You need minimal upkeep on aluminum buildings because this material lasts longer than wood or steel stuff.

Example:

A business skyscraper topped with aluminum honeycomb panels would need fewer structural supports so the available money could help create better spaces both inside and out and install energy-saving technology.

4. The Design Field Uses Aluminum Honeycomb Panels For Various Applications.

Modern architectural and interior professionals use aluminum honeycomb panels because the design format can be tailored to their needs. Our products come in diverse color options with different textures which makes them both useful and visually appealing.

- Experts can make these panels match any desired shape or size.

- The product line exists in woodgrain textures alongside stone and metallic outputs.

- Modern architects and interior designers use panels of aluminum honeycomb for their projects to build walls, ceilings, partitions and decorative elements.

Example:

Luxury hotels that use aluminum honeycomb panels for ceiling and room partitions achieve a stylish modern style plus lasting performance.

5. The Materials Conserve Natural Resources And Protect The Environment.

Due to its importance in modern construction sustainability projects, aluminum honeycomb panels serve as a sustainable option when replacing conventional building materials.

- Aluminum remains fully recyclable through endless cycle reprocessing.

- These panels create less pollution and use fewer transportation fuel and power.

- LED-certification supports buildings in getting official green building status.

Example:

A sustainability-certified public project would achieve its environmental goals by choosing aluminum honeycomb panels.

Different Industries and Large Projects Can Use Aluminum Honeycomb Panels

Some of the most common industries using these panels include:

- Office towers work side by side with shopping malls and business centers as commercial property clients.

- Construction efforts employ these panels for their projects on bridges, tunnels and airport runways.

- Aluminum honeycomb panels support aircraft wings and vehicle doors plus high-speed rail and electrical car production.

- Marine industries use aluminum honeycomb panels for their boats, ships, and offshore energy operations.

Learn Proper Methods for Choosing Excellent Aluminum Honeycomb Panels

To maximize the benefits of these material, contractors should consider:

- Selection of panel thickness and core density depends on the project’s structural requirements at hand.

- For outdoors, apply weatherproof surface treatments when selecting panels.

- Source trusted aluminum sheet manufacturers to get strong materials in your project.

Conclusion

Building projects now use aluminum honeycomb panels because they provide outstanding strength at a low price and stay durable for a long time. These panels have basic weight properties that benefit large construction works while their multiple looks benefit building designs.

Contractors seeking perfect material balance should pick aluminum honeycomb panels for today’s best options. The construction world will continue to use aluminum honeycomb panels as its main building solution because of their ongoing industry advancements.

Should you try aluminum honeycomb panels for your next big construction job? Let us know your thoughts!