Boost Efficiency with Lightweight Composite Honeycomb Panels: Key Features and Buying Tips

The business landscape is evolving rapidly, and so is the need for modern, efficient, and cost-effective materials for construction, design, and industrial purposes. Small business owners are constantly in search of innovative solutions that not only streamline their operations but also align with the demand for sustainable and durable choices. One such versatile and innovative material gaining attention is Lightweight Composite Honeycomb Panels.

These panels are transforming industries with their unique structure, combining strength, sustainability, and adaptability. From making buildings lighter yet stronger to saving costs in transportation, composite honeycomb panels are a game-changer for small businesses seeking efficiency. This article provides a comprehensive overview of these panels, highlights their key features, and offers detailed buying tips with real-world applications to help you understand their true potential.

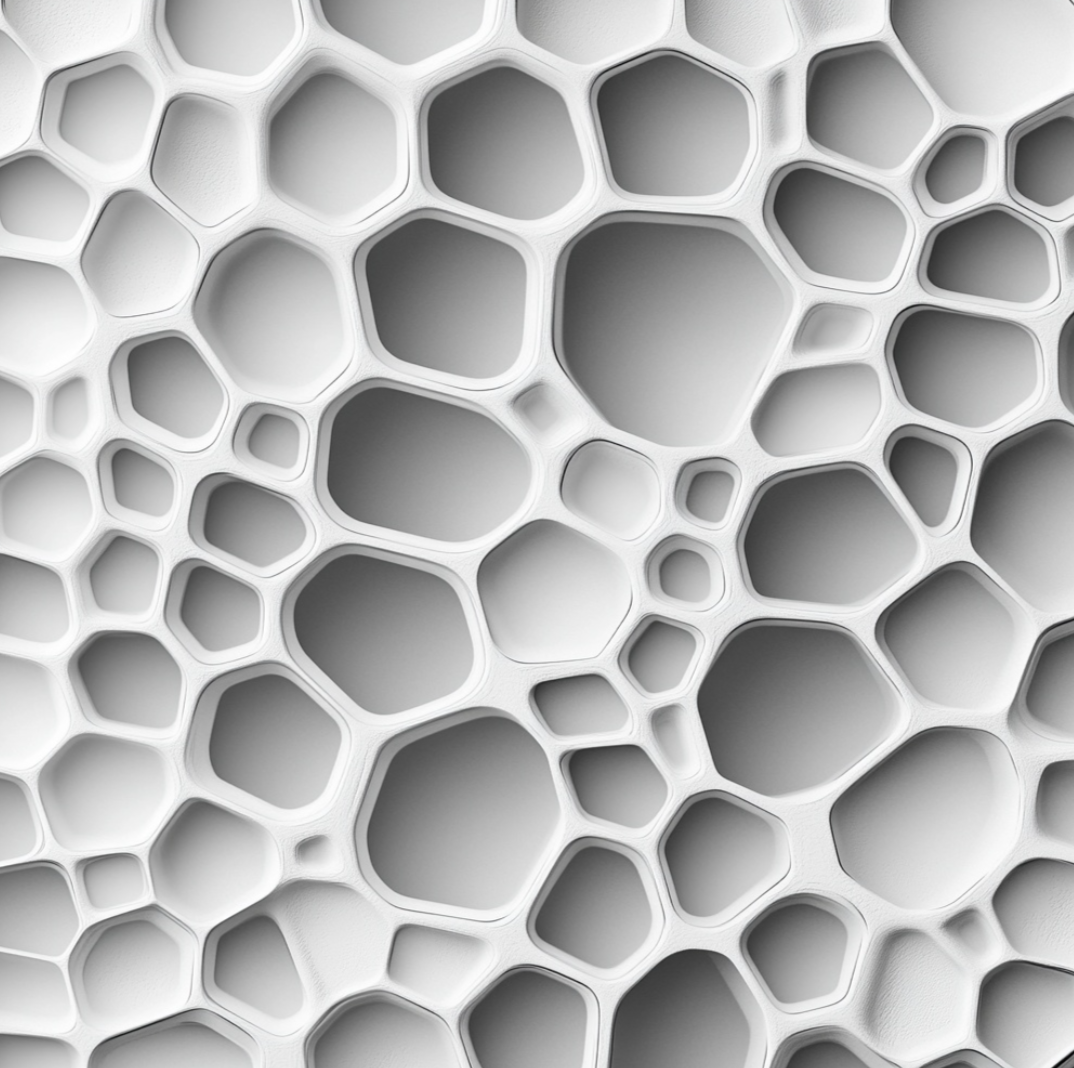

What Are Lightweight Composite Honeycomb Panels?

Lightweight composite honeycomb panels are advanced structural materials constructed using a honeycomb-shaped core that’s sandwiched between two thin, durable layers, commonly referred to as face sheets. The honeycomb structure is a hexagonal grid design, engineered to provide maximum strength with minimal material usage, resulting in outstanding strength-to-weight ratios.

Face sheets are typically made from sturdy materials such as aluminum, fiberglass, or carbon fiber, while the core can be made from materials like thermoplastics, metals, or paper-based composites. This combination of materials ensures that the panels deliver exceptional performance tailored to specific applications across various industries.

Key Features of Lightweight Composite Honeycomb Panels

Understanding the standout features of lightweight composite honeycomb panels is crucial for unlocking their full potential. Below is an in-depth dive into the attributes that make these panels so advantageous.

1. Weight Efficiency with High Functionality

- Significant Weight Reduction: The honeycomb structure minimizes the amount of material within the core, making the panels extremely lightweight.

- Ease of Transportation and Handling: For small business owners, lighter materials mean lower transportation costs and easier on-site handling, reducing time and labor expenses.

- Better Load Balancing: Despite their lightweight form, they distribute loads effectively, making them suitable for crucial structural uses in construction, aviation, and even logistics.

Example Use Case: A small interior design firm incorporated lightweight panels in furniture construction. Due to their ease of handling, panels reduced assembly time, improved ergonomics, and decreased transportation expenses for large orders.

2. Unmatched Strength-to-Weight Ratio

- Durable Yet Light: Composite honeycomb panels are engineered to resist significant loads and impacts, which is essential for both safety and operational efficiency.

- Protection in Adverse Conditions: The panels offer excellent resistance to deformation, making them ideal for areas prone to heavy use or harsh conditions.

- Thin But Uncompromising: Thin face sheets, backed by the honeycomb structure, deliver strength comparable to thicker traditional materials at a fraction of the weight.

Example Use Case: A small business in the automotive industry utilized lightweight honeycomb panels for vehicle interiors to reduce car weight, increasing fuel efficiency while retaining strength in safety-critical areas.

3. Exceptional Versatility in Application

Composite honeycomb panels can be customized and adapted to meet a variety of functional needs. Popular application areas include:

- Aerospace and Defense: Due to weight reduction and high strength, honeycomb panels are routinely used in aircraft components.

- Architecture and Interior Design: Panels can be used for ceilings, flooring systems, cladding, or even decorative furniture.

- Marine and Transport Industries: With natural resistance to corrosion and water, lightweight panels are widely used in boat hulls, ship decks, and transport containers.

Example Use Case: A small-scale architecture firm introduced these panels into modular home construction, reducing build time while offering energy efficiency and appealing aesthetic customization.

4. Innovative and Eco-Friendly Construction Material

Modern businesses are increasingly sensitive about sustainability and reducing environmental footprints. Lightweight composite honeycomb panels align perfectly with these goals:

- Recyclable Materials: Many panels are crafted using eco-friendly or recyclable core materials and face sheets.

- Waste Minimization: The lightweight design uses less raw material, conserving resources during construction.

- Reduced Energy Consumption: The ease of transportation and installation also minimizes the carbon footprint associated with these processes.

Example Use Case: A small packaging company utilized lightweight panels for custom shipping containers, reducing waste while creating eco-friendly, reusable solutions for fragile cargo shipping.

Buying Tips for Lightweight Composite Honeycomb Panels

For small business owners aiming to incorporate lightweight composite honeycomb panels into their operations, making an informed purchasing decision is key. Below are detailed tips to help you source the right panels based on your business needs:

1. Evaluate Quality and Certification Standards

- Ensure the products meet essential global certifications for safety and construction standards.

- Work with reputable and experienced suppliers known for producing consistently reliable panels.

2. Customization Options Matter

Almost every small business operates with unique project requirements. Ensure the supplier offers customization options such as:

- Core Material Choices: Depending on your use, you may need options like thermoplastic, aluminum, or fiberglass cores.

- Face Sheet Customization: Select materials resistant to corrosion, weather, or fire if required.

Note: Customization ensures compatibility with your operational needs while optimizing cost efficiency.

3. Understand Panel Longevity and Environmental Resistance

Weather conditions, wear & tear, and environmental exposure can affect panel performance. Look for:

- Resistance to humidity, heat, cold, and UV exposure for outdoor applications.

- Surface sturdiness for abrasion or chemical exposure.

Investing in higher-quality high-strength panels with superior resistance pays off in long-term value.

4. Focus on Affordability and Overall ROI

While lightweight panels may seem like a premium option upfront, they often lead to operational savings that outweigh the investment.

- Compare prices from multiple suppliers and evaluate warranties.

- Assess cost savings in terms of reduced labor, transport, and maintenance over traditional materials.

Real-World Case Studies

- Modular Office Space Construction

A small construction startup adopted lightweight composite honeycomb panels to design modular office pods. By reducing installation time by 40% and transit weight by nearly 30%, the business achieved quicker turnaround times while cutting costs. - Eco-Friendly Retail Displays

A retail business employed lightweight panels for creating portable display units. The modular yet durable nature of the panels allowed easy relocation without compromising on structural stability, significantly enhancing retail efficiency. - Shipping Industry Modernization

A logistics company replaced traditional wooden crates with lightweight panels for shipping delicate goods. This minimized shipping damage, reduced shipping costs due to decreased weight, and showcased the company’s commitment to sustainable practices.

Concluding Thoughts

Lightweight composite honeycomb panels are a game-changing solution for small business owners looking to improve efficiency, decrease costs, and adopt a sustainable approach to their projects. The exceptional strength-to-weight ratio, versatility, and eco-friendliness place these panels at the forefront of modern construction and design materials.

For small businesses, adopting advanced solutions like composite honeycomb panels is not just a trend – it’s a necessity to remain competitive in today’s fast-paced market. Taking the time to evaluate the panels’ key features and following the outlined buying tips will ensure your investment directly supports your operational goals.

By incorporating lightweight panels into your projects, you not only save on logistics and material costs but also position your business as an innovative and eco-conscious player in your industry. Embrace the possibilities of lightweight composite honeycomb panels and unlock efficiency like never before!