Aluminium Honeycomb Panel: Key Features, Applications, and Buying Guide

In this comprehensive guide, we’ll dive into the key features of aluminium honeycomb panels, explore their diverse applications, and provide you with an expert buying guide to make informed decisions for your project.

Key Features of Aluminium Honeycomb Panels

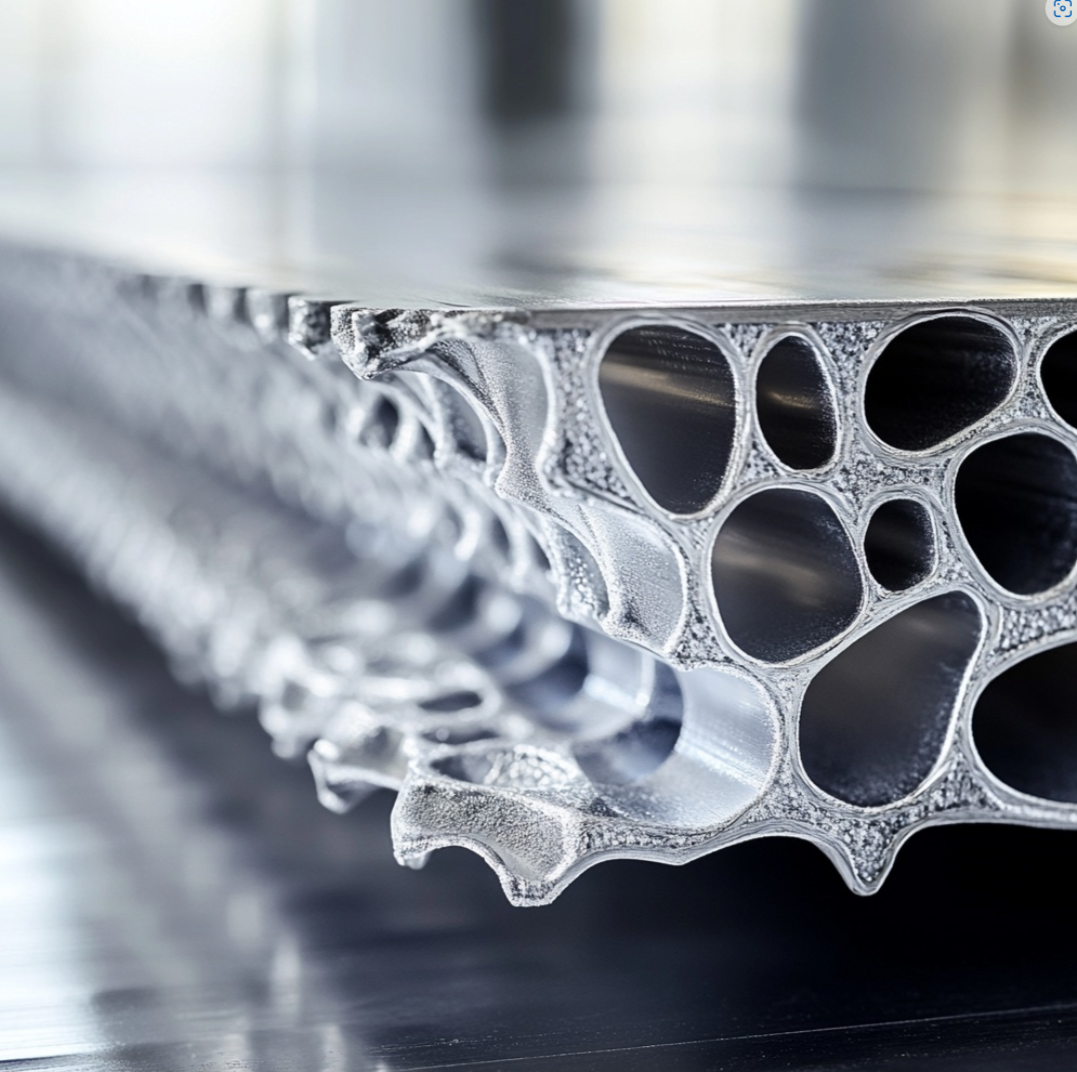

Aluminium honeycomb panels derive their name from the honeycomb-shaped core sandwiched between two durable aluminium sheets. It’s this unique structural formation that gives them their impressive properties, allowing them to outperform traditional materials in several ways. Below, we’ll uncover these features in detail:

1. Lightweight Yet Structurally Robust

At the core of an aluminium honeycomb panel lies its hallmark feature – the strikingly high strength-to-weight ratio. The honeycomb core is made up of hexagonal cells that create a natural geometry capable of distributing weight evenly, minimizing the overall material used while retaining superior strength. This makes the panels:

- Lightweight to handle, transport, and install.

- Easier to integrate into large projects without overburdening the structural framework.

- The ideal choice for applications where weight is a key consideration, such as aerospace manufacturing.

For instance, the use of aluminium honeycomb panels in commercial aircraft results in dramatically reduced weight, improving fuel efficiency and reducing operating costs.

2. Exceptional Durability and Longevity

The combination of the honeycomb core and outer aluminium sheets ensures that these panels can withstand significant forces without warping, deforming, or deteriorating. Some key benefits include:

- Impact and Weather Resistance: Aluminium honeycomb panels remain unaffected by rain, UV exposure, and temperature fluctuations, making them perfect for outdoor applications such as cladding systems.

- Corrosion Resistance: Aluminium’s natural oxidation creates a protective layer that prevents corrosion and rust, ensuring a long lifecycle.

For example, in coastal environments where exposure to salt and moisture is considerably high, the use of corrosion-resistant aluminium honeycomb panels as cladding often outperforms traditional materials like wood or steel.

3. Energy Efficiency and Fire Resistance

The thermal properties of aluminium honeycomb panels enhance a building’s energy efficiency. The honeycomb structure provides natural insulation, helping maintain internal temperatures in both hot and cold climates. Additionally, many aluminium honeycomb panels are fire-rated, offering:

- Heat resistance to mitigate the spread of flames.

- Compliance with building safety standards.

This makes them especially popular in high-rise commercial buildings or industrial settings where safety and energy efficiency are priorities.

4. Design Flexibility and Modern Aesthetics

The versatility of aluminium honeycomb panels allows them to cater to a variety of design needs. With options for finishes such as brushed aluminium, wood-like textures, matte colors, and even custom-printed designs, these panels are a go-to choice for architects and interior designers aiming to create sleek, contemporary spaces. Leveraging these materials, you can design:

- Futuristic facades and cladding systems.

- Elegant furniture and interior partitions.

- Unique display units for retail shops.

Popular architectural landmarks like Dubai’s modern skyscrapers and luxury yachts are examples of projects where aluminium honeycomb panels have contributed to both form and functionality.

Applications of Aluminium Honeycomb Panels

The versatility and reliability of aluminium honeycomb panels have made them a central material across numerous industries. Let’s explore their importance in different domains:

1. Aerospace Industry: Pioneering Efficiency in Aviation

The aerospace sector has been a pioneer in adopting aluminium honeycomb panels, using them to design lightweight components without compromising on strength. Key applications include:

- The construction of airplane cabin interiors such as overhead storage, bulkheads, and flooring panels.

- Satellite and spacecraft parts, where weight reduction is crucial for functionality and launch cost-efficiency.

Case Study: In the development of the Airbus A350, aluminium honeycomb panels have been used extensively in the fuselage, enhancing fuel efficiency while maintaining passenger safety.

2. Automotive Sector: Enhancing Vehicle Efficiency

The automotive industry leverages aluminium honeycomb panels for lightweight, high-performance vehicle components. Common applications include:

- Door panels and trunk floors to reduce vehicle weight, which directly boosts fuel economy.

- Crash protection barriers that combine lightweight properties with energy absorption capabilities, enhancing vehicle safety.

For instance, electric vehicle (EV) manufacturers use honeycomb panels to extend driving range by minimizing vehicle weight, critical for battery-powered models.

3. Construction Industry: Building Sustainable and Creative Spaces

In construction, aluminium honeycomb panels are considered innovative building materials integral to modern architectural designs. Applications consist of:

- Exterior Cladding Systems: Lightweight structural panels provide modern aesthetics while protecting buildings from weather conditions.

- Ceiling and Wall Panels: Often used in airports, shopping malls, and modern residential projects to create clean, seamless surfaces.

- Revolving Doors: Honeycomb panels are ideal for revolving doors due to their strength and lightweight nature, ensuring smooth and extended operation.

Example: The use of these durable aluminum panels in futuristic skyscrapers like London’s “The Gherkin” has showcased their potential to merge aesthetics with practicality.

4. Interior Design: Redefining Modern Spaces

Within interior design, aluminium honeycomb panels bring limitless creativity to life. Their applications include:

- Office Partitions: Sleek panels offer premium aesthetics while maintaining lightweight ease of installation.

- Furniture Manufacture: Used in making desks, shelves, and cabinets that are both visually appealing and long-lasting.

- Retail Displays: Create unique and customizable displays optimized for retail environments.

Example: Leading retail brands frequently use aluminium honeycomb panels for customized shelving systems that are modular, stylish, and incredibly durable.

5. Marine & Rail Applications

The marine and rail transport industries also benefit greatly from the use of aluminium honeycomb panels. Properties such as resistance to water, salt, and vibration make them suitable for shipbuilding materials, interior train components, and more.

Expert Buying Guide for Aluminium Honeycomb Panels

Selecting the right aluminium honeycomb panel for your project requires thoughtful consideration of your needs and specifications. Follow these detailed steps to ensure you make the right choice:

1. Analyze Project Scope and Requirements

Begin by understanding your project’s unique demands. Key considerations include:

- Panel Dimensions: Determine the size and thickness based on intended use. For example, aerospace panels are significantly thinner than cladding panels for buildings.

- Aesthetic Preferences: If appearance matters, explore finish options like anodized aluminum, powder coating, or imitation wood textures.

2. Assess Specifications and Quality Standards

The quality of aluminium honeycomb panels can vary greatly, and it’s essential to choose products that meet industry standards. Look for certifications such as:

- ISO standards for quality control.

- Fire and corrosion resistance certifications.

Pro Tip: Validate the specifications with real-world case studies or reviews from other buyers to ensure reliability.

3. Compare Supplier Options

Not all suppliers offer the same level of quality, customization, or service. While evaluating options:

- Prioritize companies with established expertise in manufacturing lightweight structural panels.

- Seek bulk discounts but ensure quality isn’t compromised for cost savings.

4. Consider Installation and Long-Term Maintenance

Ease of installation is a key factor, especially for large-scale projects. Opt for manufacturers who provide detailed installation guides or support services. Simultaneously, analyze the maintenance required:

- Panels with weather-resistant coatings are easier to maintain in the long run.

- Customizable options with anti-scratch finishes ensure longer aesthetic appeal.

5. Evaluate Pricing vs. Durability

While aluminium honeycomb panels are more cost-effective in the long term due to their durability, the initial investment can be high. Balance your budget by choosing a reliable supplier who offers superior materials at competitive rates.

Conclusion

Aluminium honeycomb panels have emerged as a cornerstone of modern engineering and design. By combining unparalleled strength with lightweight efficiency, they are revolutionizing construction, aerospace, automotive, and countless other industries.

From stunning facades and energy-efficient cladding systems to lightweight aircraft components, their applications are only limited by imagination. To harness their potential, ensure due diligence while purchasing by evaluating key features, application-specific needs, and quality standards.

In embracing innovative materials like aluminium honeycomb panels, you not only enhance performance and aesthetics but also contribute to building sustainable and future-forward projects.