What Are Aluminum Honeycomb Panels?

Introduction

Aluminum honeycomb panels are what, in times to come, promises to be a wonder material with much strength in lightness and versatility for construction and contemporary design. This is where the company Wyndor has developed the front regarding panel development to put up with demands that keep altering in architecture. A new revolution in this regard brings about construction getting enabled to become very strong through honeycomb panels on light frames. Its nature-inspired patterning ideas have turned it into creating extensive functionalities, ranging from commercial projects to designing for houses. This article discusses the different compositions of aluminum honeycomb panels, their method of manufacturing, and numerous advantages derived from the application of these panels and has become very relevant in modern architecture.

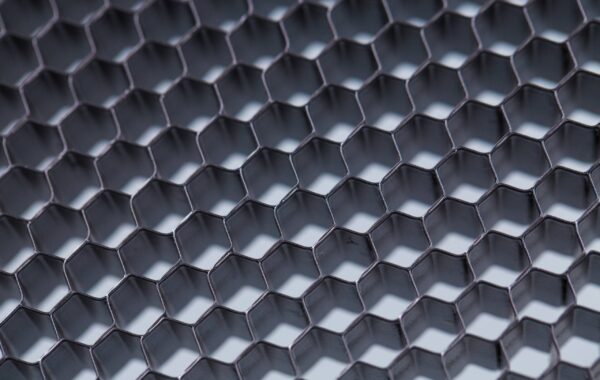

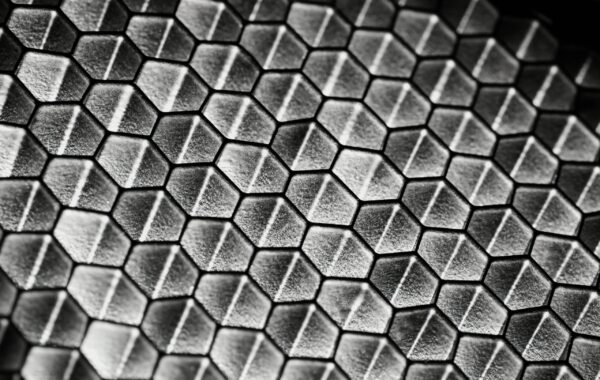

Understanding Aluminum Honeycomb Panels

Panels, having a hexagonal core made of aluminum that is sandwiched with two skins of aluminum sheets, efficiently replicates nature through the honeycomb-the former beehives, it has an extremely high ratio of strength and weight, and thus, the core of the panels will be lightweight and rigid to guarantee the longevity of the structure while highly handy and convenient to install.

How They Are Manufactured

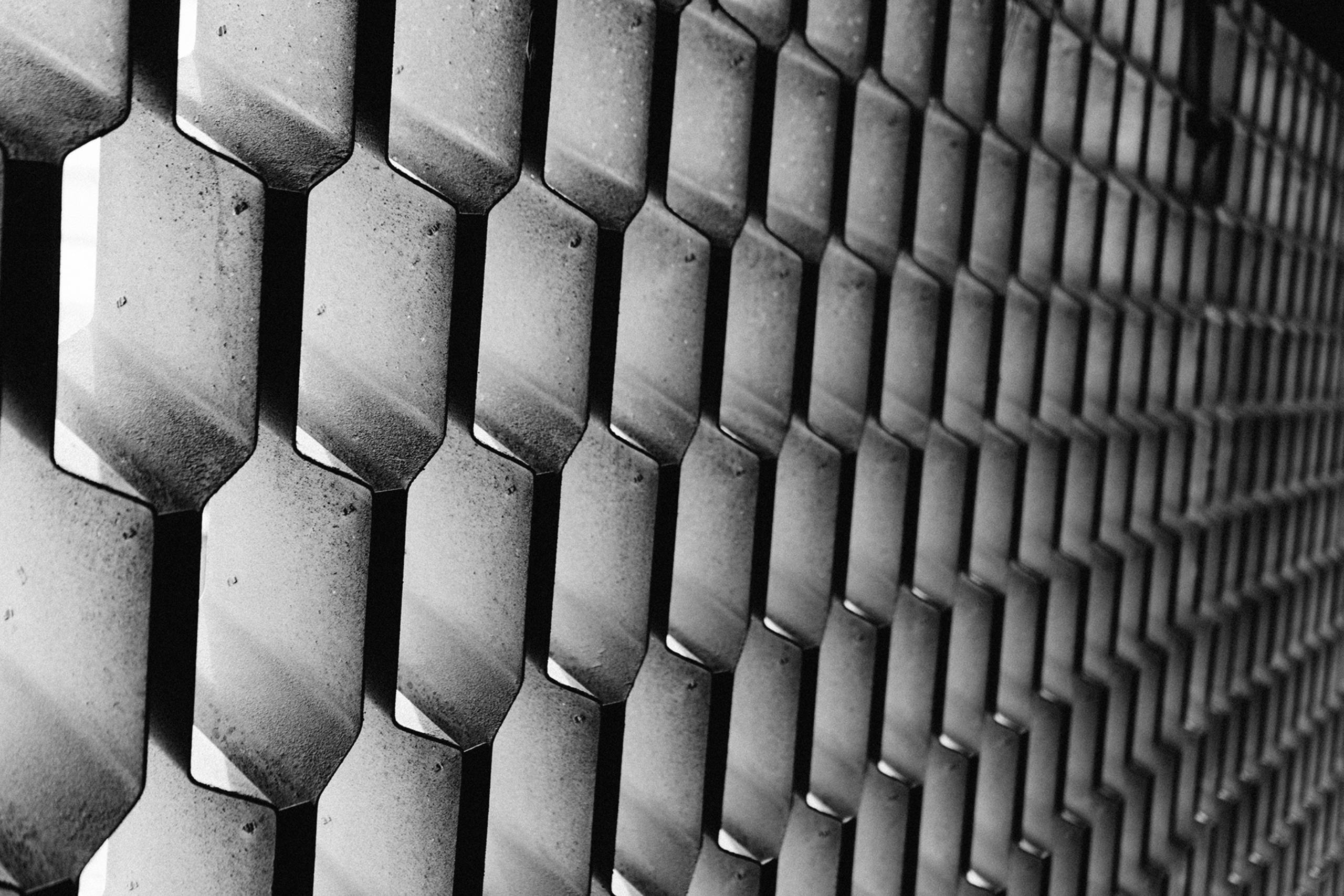

Core Preparation: The foil is cut and formed into a hexagonal structure. The honeycomb core that this formed is very light in weight but possesses quite a lot of rigidity.

Face Sheets Bonding: Both faces of the honeycomb core are bonded to thin aluminium sheets by high-strength adhesive. The choice of such adhesive is judicious so that the adhesive would bond well to the material and possess resistance to environmental stresses.

Cure: The panel is allowed to cure with controlled heat and pressure. It is a critical process that enables the adhesive to take its position for durable long term and strength.

Finishing: Panels are cut to size after curing and then finished with coatings or laminates as per design specifications. Finishes can be as simple as anodized aluminum or in any paint color or pattern desired, so a great variety of aesthetics is possible.

Key Benefits of Aluminum Honeycomb Panels

Strength and Durability

Wyndor’s aluminum honeycomb panels have exceptional strength and durability. The core of aluminum honeycomb panels, in the shape of regular hexagons, assures a very good ratio of strength and rigidity. Such construction enables the panel to withstand substantial load without deforming, hence serving perfectly for places where extreme structural integrity is demanded. In addition, the impacts, vibrations, and other environmental factors concerning changes in moisture and temperature on panels ensure that its performance may endure for a considerable period.

Lightweight

Among the many important features of aluminum honeycomb panels, lightweight definitely stands out. While all these panels are extremely strong, they are much lighter compared to conventional materials like solid aluminum or steel. The lightweight property ensures better and easier transportation and installation processes, which saves a lot of labor and time. Besides, it causes less weight, leading to overall energy efficiency in places where it may be used for transportation purposes, facilitating fuel economy.

Customization

Wyndor provides comprehensive customization options in its aluminum honeycomb panels for meeting diversified design needs. Aluminum honeycomb panels are highly customizable to suit various design requirements. They can be manufactured in various thicknesses, sizes, and finishes, thus allowing architects and designers to adapt the panels according to particular project requirements. Be it a sleek and modern office interior or durable industrial enclosure, these panels can be customized in such a manner so as to enhance functionality with style.

Eco-Friendly

In a time when sustainability is the keyword, the properties of aluminum honeycomb panels stand out as being extremely eco-friendly. The paneling material can be made from recyclable material, and being lightweight, reduces the carbon footprint of transportation to a minimum. Moreover, with the long lifespan of the paneling, replacements become less frequent, hence resulting in lesser wastes and resources being used in the long run.

Zero Formaldehyde

Formaldehyde is a type of VOC commonly used within many traditional building materials, and aluminum honeycomb panels do not possess this chemical. With this in mind, these panels are therefore not just a healthier but also much safer alternative when used indoors, ensuring healthier air and hence minimizing VOC risks to human health.

Moisture and Heat Resistance

The panels are resistant to moisture and heat; therefore, they are suitable for areas with high humidity or those that have fluctuations in temperature. They neither warp, swell, nor deteriorate under such conditions; thus, they always assure performance and appearance. This makes them very suitable for applications like kitchen cabinetry, bathroom partitions, and exterior cladding.

Low Maintenance

Long-term, the aluminum honeycomb panels are quite cost-effective since they need little maintenance. Being resistant to corrosion, moisture, and wear, it retains its appearance and structural integrity with minimal upkeep. This reduces the amount of time that is spent in constant repairs or replacement, which, in turn, saves building owners and facility managers a lot of time and money.

Aluminum Honeycomb Panels Uses

For Interior Designers

Interior designers can develop modern and functional interior spaces based on the flexibility that is accorded by aluminum honeycomb panels. They are applied in wall cladding, partitioning, ceiling, and even furniture. Designers, through their versatility in terms of available finishes and hues, get to realize whatever aesthetic desired while providing durability with minimal maintenance efforts.

For Factories and Contractors

Aluminum honeycomb panels are much appreciated in industry as they provide high strength but are light. Factories and contractors use such panels in a wide range of applications, including enclosures for machine, clean rooms, transportation vehicles, and many others. Their simple installation and outstanding durability at extreme conditions make them a cost-effective solution for heavy industrial projects for house owners.

These aluminum honeycomb panels could be used to enhance various facets of residential sectors. This includes cabinetry, countertops, and flooring, among several others. The trendy look, fewer maintenance requirements, yet high performance of the aluminum honeycomb panels make them an attractive add-on to uplift functionality and beauty for interior improvement in homes.

Conclusion

Aluminum honeycomb panels are indeed one of the greatest advances in building materials because they provide reliability in high-strength performance, environmental sustainability, and lightness. They can be used in a variety of designs and applications in varied projects, from commercial buildings to private homes. The demand for innovative and eco-friendly materials is rising, and with this, the aluminum honeycomb panel is poised to play a great role in the future of architecture and design. By choosing these panels, builders, designers, and homeowners can achieve superior performance and aesthetics while contributing to a more sustainable built environment.